According to a report by the MCA, Australia has invested $30 billion in research and development of the mining sector since 2005.

This has led to a series of important products which streamline mining efforts and ensure workers are protected. This list of 10 significant innovations in mining highlights the power of technology in shaping modern industries.

Infra-red thermal camera

In 2015, Peabody Energy Australia was awarded first place at the Queensland Mining Industry Health and Safety Conference for their infra-red thermal camera. The camera was intended to reduce the risks of operating heavy machinery in small spaces or low visibility by allowing the operator to identify people in traditional blind spots.

By using heat instead of light, the camera can identify people, machines and cables even in dark environments. Heat can be detected from up to 500 metres away, allowing enough time for a driver to react before causing damage.

RGR Velox © GroundProbe

Radar Monitoring

GroundProbe is an Australian based company that specialises in the detection of geohazards.

In 2021, they launched RFR-Velox, a reactive monitoring and alarm system designed to detect and track geohazards in real time. It was intended for use in tailings dam breaches, immediately alerting workers if a failure occurs to prevent the damage of equipment or loss of life. Users are able to closely monitor wall movement and determine the likelihood of collapse, giving them enough warning for an adequate response.

The radar was designed to adapt to any terrain or weather condition. The advanced detection capabilities, which allow the radar to detect broken ground within a 5.6km area, ensure everyone can feel safe while out in the field.

Mine haulage vehicle

Rexx is a mining haul truck designed by Western Australian company, Bis Industries. Measuring only 4.8 metres wide, the truck has a tight turning radius and can handle gradients up to 12 percent. It can also drive along narrow haul roads to deliver loads to difficult locations. The truck can travel up to 40 kilometres fully loaded, and saves between 20 to 30 percent of its fuel in the process, making it an economical and efficient mining vehicle.

Rexx has also been built with energy adaptability to accommodate future hybrid, electric or hydrogen platforms.

The truck is fitted with 360-degree cameras, fatigue detection and driver monitoring systems which lead to better overall safety outcomes.

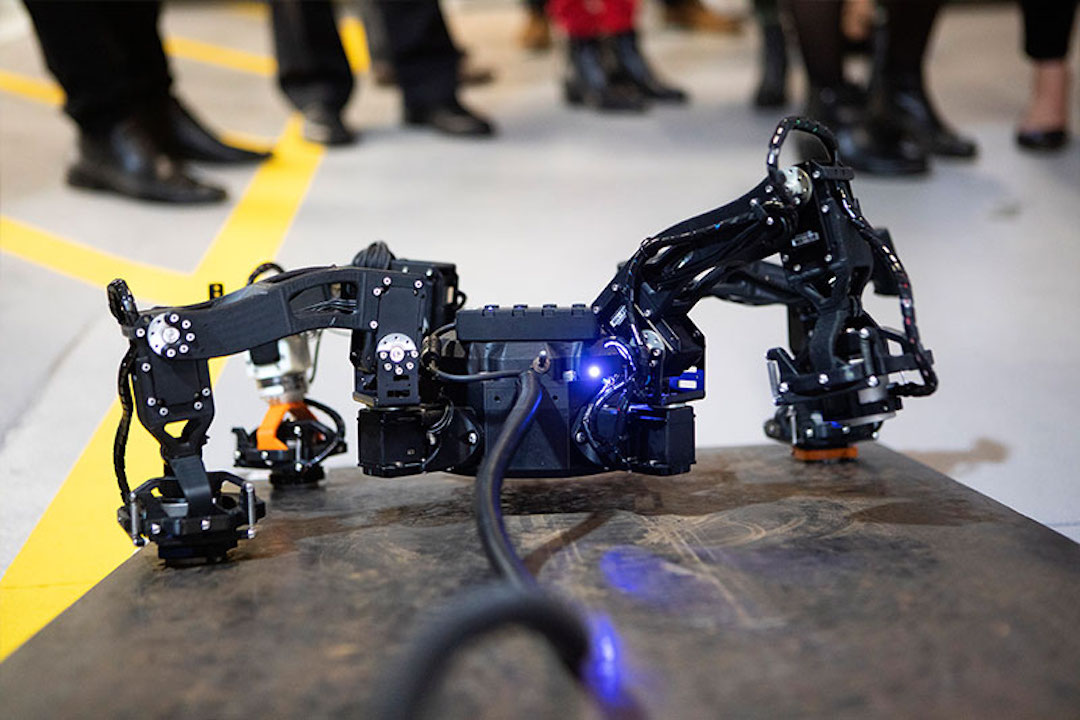

Magneto robot © Nexis

Robotic camera inspection device

WA-based robotics company Nexxis, launched the world’s first EX-rated robotic camera inspection device, known as Magneto-EX, in 2021.

Confined spaces are one of the most dangerous terrains for mine workers, leading to a high proportion of accidents. The spider-like frame of Magneto-EX allows it to enter tight spaces and explore areas where humans cannot or should not go. The small robot is fitted with magnetic feet to allow for hazardous area inspections on mining sites, and AI technology enables the inspection of vertical structures, gathering data to report back to system operators.

Survey drones

Trinity Pro is a winged mapping drone designed to capture aerial data for better coverage of mining sites. Released by Quantum Systems, the drone can cover an area of 700 hectares, and fly for up to 90 minutes at one time.

Quantum has released a large selection of sensors, which can be swapped over in the drone depending on the necessary surveying applications. The drone can assist in 3D photogrammetry, distance measurements, terrain models, and more.

The drone has also been developed in order to take off and land from different locations, with a downwards facing camera to assist with terrain avoidance and safe landings.

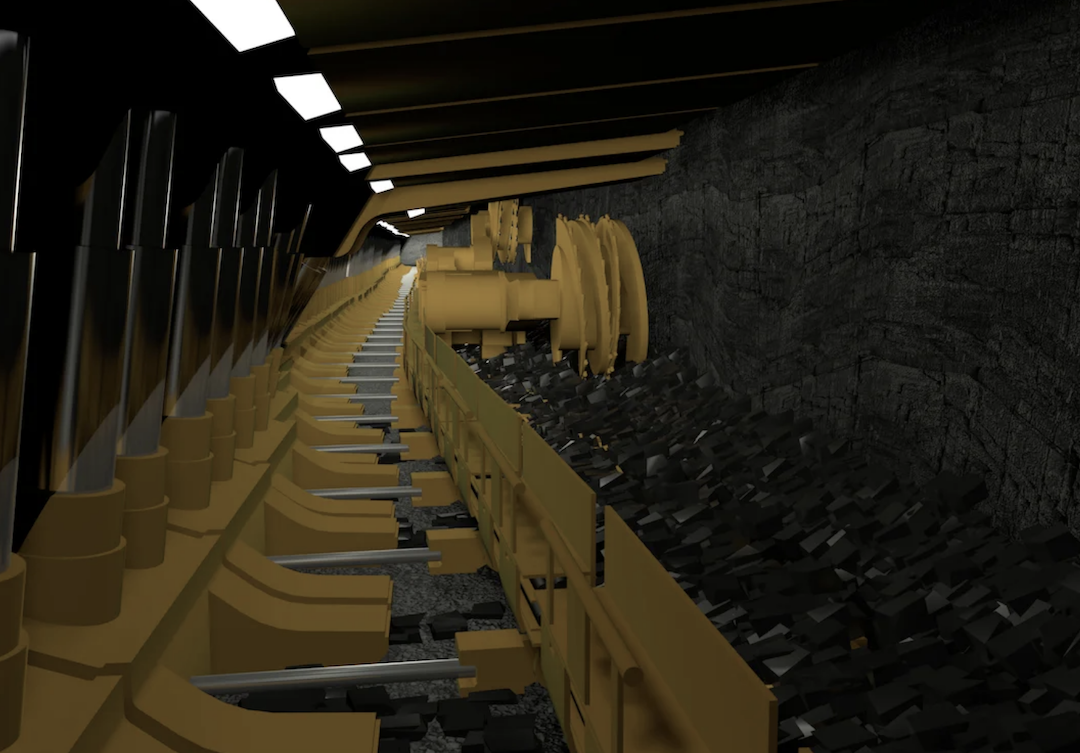

Longwall Automation

According to the CSIRO, longwall mining accounts for 90 percent of Australia’s underground coal production. Typically, a mechanical shear will cut along the coal seam, exposing miners to health and safety risks.

In response, the CSIRO has developed an underground automation system which uses remote guidance technology to steer equipment. This removes workers from direct hazards while also streamlining the process of longwall mining.

Graphic of longwall automation © CSIRO

Fleet Management

Aptella, an Australian automation and positioning tech company, has developed a way for managers to keep track of their mining operations. iVolve is a fleet management system which provides a window into all site operations. It uses map-based visualisation tools to track the fleet in real time, providing the location and operational status of vehicles as well as the load each one is carrying.

The software can also be used to analyse the history of the fleet, including movements, operator lists and transported materials.

SafetySpear

One of the biggest hazards in underground mining is injury as a result of falling objects. In response, RattleJack developed the SafetySpear, a solution to stop falling drill rods from causing serious incidents. The SafetySpear works by plugging drilling blast holes with a lightweight, high-impact material. It activates when hit with any downwards force, protecting workers from falling hazards.

The SafetySpear can be installed by one individual within minutes, making it an economic solution as well. The multi stage design allows it to continue expanding during use, ensuring complete protection.

Cave Tracker

Cave Tracker is a real-time measurement of the movement of fragmented rocks developed by Mining3, Newcrest Mining, Rio Tinto and Elexon. It works using magnetic beacons inserted into a body of ore and spun at a certain speed to create a magnetic field.

This field, which mitigates the need for battery power, can be detected from more than 200 metres away, picked up by detectors which can then determine the 3D location of a cave in real time. This enables mining workers to pinpoint which parts of a cave are moving and which parts are stagnant.

Fatigue monitor © SmartCap

Fatigue Monitor

The LifeBand is a fatigue monitoring system developed by SmartCap. It can be integrated into headwear such as caps, hard hats, or even headbands, making it an easy tool to operate. The device is connected to the Life App, which provides users with visual and audible alerts when they become fatigued.

The system works by measuring brain activity and determining a user’s level of alertness. The program then offers real-time feedback and alerts to keep the individual safe.

To read an outlook on Queensland’s mining sector for 2024, click here.