Researchers are using spinning fibres to support development in the Northern Territory.

Using a high-end nanofibre fabrication facility on the Casuarina Campus, researchers from Charles Darwin University (CDU) are developing fibres 10 to 100 times finer than spider’s silk to fix pressing issues in the Northern Territory.

Why nanofibres?

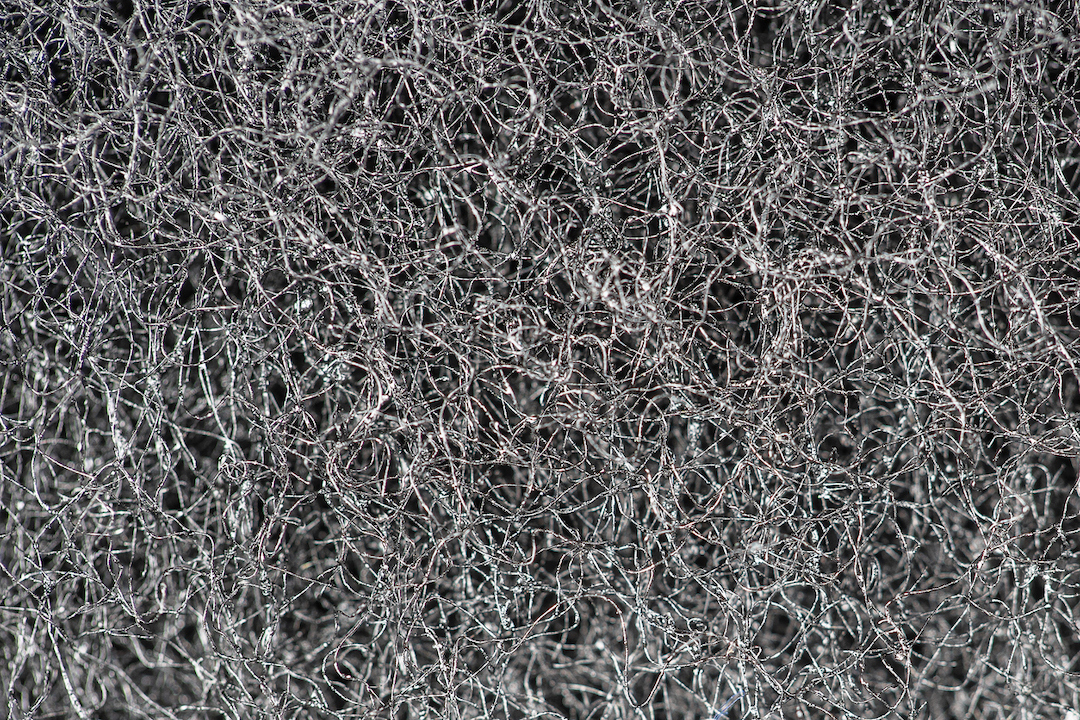

Nanofibres are a lightweight material with a diameter of around 1/1000th of a human hair. The high surface area to volume ratio means they have a large amount of active surface on a tiny space. Whether capturing light, absorbing impact or bonding with other materials, this characteristic results in an outsized performance capability and allows nanofibres to interact effectively with a variety of environments.

Currently, fibres created using electrospinning are found in bulletproof vests, filters for water purification and medical equipment.

Nanofibres can be spun using many different materials including collagen, keratin and gelatin. The electrospinning technique involves stretching a liquid droplet to form fibres under a controlled electric field. According to NanoScience Instruments, this process can be undertaken at room temperature, making it versatile and energy-efficient.

An article in the Nature Reviews journal goes further to assert that nanofibres can be applied from laboratory to industrial scales, for conventional and emerging applications. The versatility of electrospun products makes them suitable for use in environmental, energy, textiles, agriculture and medical sectors.

Nanofibers will be used in the NT for clean water and clean energy.

How will they be used in the NT?

Leading the current research is Dr Naveen Kumar Elumalai from CDU Faculty of Science and Technology, who wants to examine how nanofibres can be used in everyday life by improving their strength and ability. Dr Elumalai has been honoured as one of the top two percent of scientists globally in 2022, 2023 and 2024 by Stanford University.

With this new project, his team is particularly concerned with application in the defence industry.

“Kevlar vests and other protective clothing which our police and defence force wear are currently quite heavy and lack breathability, which is not ideal here in the NT,” Dr Elumalai said.

“Utilising nanofibres will help to make the vests stronger without increasing the weight. This means that they will offer greater protection for wearers against things such as bullets and shrapnel without making them hotter, this is for sure a win-win.”

Another area of focus in the Northern Territory is air and water purification. Many First Nations Communities suffer from poor water quality, which can impact overall economic and health outcomes.

“We are trialling the use of nanofibre technology when it comes to air and water purification as the nanofibres can be formed to make a mesh like substance which can help to stop bacteria from entering the water or air and filter out contaminants,” Dr Elumalai said.

“This could really be transformative when it comes to the health and longevity of our communities and is cost effective as well.”

Nanofibre technology is lightweight and highly effective.

Along with cleaner water, the team has turned their attention to cleaner energy. They have developed special nanofibres which can split water molecules to produce hydrogen, when released into the water and exposed to sunlight.

“This technology is particularly promising for Darwin and the Northern Territory,” Dr Elumalai explained.

“It could help address our energy needs using just water and sunlight, without the need for complex systems. Imagine being able to produce hydrogen fuel directly from water – it’s a game-changer for sustainable energy production in our region.”

While there is more work to be done, the team are excited by their progress and the possible implications for the future.

“I look forward to furthering our research and working with industry groups to implement nanofibre technology,” concludes Dr Elumalai.

To read about the impact of artificial light on sleep cycles, click here.