Graphene is the secret ingredient to unlocking concrete recycling.

A new study led by Flinders University and the University of Melbourne has found that combining concrete with graphene can enhance recyclability and combat carbon emissions.

Cementing concerns

Concrete is the most common construction material on the planet. However, it is also a large contributor to global greenhouse gas emissions. According to Princeton University, the production of concrete releases 4 billion tonnes of carbon dioxide annually. This is around 8 percent of overall global emissions.

Similarly, concrete is responsible for the utilisation of 30 percent of all non-renewable natural resources, and waste from demolition and construction is predicted to reach 2.6 billion tonnes by 2030.

These statistics highlight a major concern in the concrete industry, which currently has limited recycling capabilities for such a significant resource.

Lead researcher Dr Aliakbar Gholampour with the concrete aggregate

Laying a new path

Concrete waste is often taken to landfill, or used as rubble when laying new roads. It is rarely given a second life, leading to higher levels of emissions.

However, Flinders University and The University of Melbourne have joined forces to examine the potential of concrete recycling. The process works by taking old, broken up concrete and producing a strong, durable new concrete by adding a small amount of graphene.

Graphene is a material extracted from graphite and consisting of pure carbon. It is 200 times more resistant than steel and five times lighter than aluminium. Graphene is a tough material, lowering the risk of corrosion and heat damage when used in construction.

According to researchers, graphene deposits are constantly being discovered and mined, reducing the price of this raw material while the cost of cement continues to rise.

According to Dr Aliahbar Gholampour from Flinders University, increasing the quality of recycled concrete through graphene will make the material more durable and versatile while simultaneously reducing emissions.

“This new form of treated recycled concrete aggregates may be more expensive to make right now, but when considering circularity and the life cycle of the materials, the costs are coming down rapidly.”

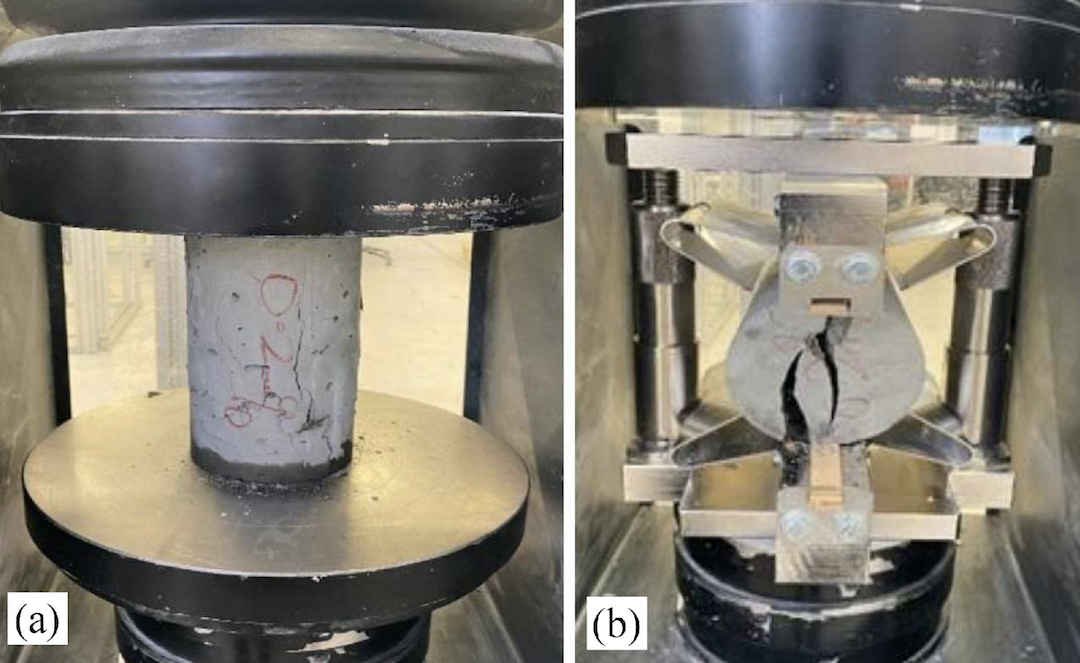

Researchers conducted several tests on the recycled concrete © Flinders University

Research into the viability of introducing graphene into concrete involved experimenting with different strengths of graphene concentration and placing these graphene-concrete mixes through a series of strength and durability tests. Overall, the study found that it was a useful solution for greater recyclability.

According to the study, “the developed concrete will be suitable for a wide range of applications where conventional high-strength concretes are currently being used, including bridges and infrastructure, high-rise buildings, marine structures, and repair and rehabilitation. However, further studies are needed to manipulate properties of graphene for different concrete grades obtained from different resources.”

While research is far from complete, the study does indicate opportunities for lowering carbon emissions and reducing the impacts of climate change.

Interested in the future of construction in Australia? Click here to discover more about 3D printed homes.